|

|

|

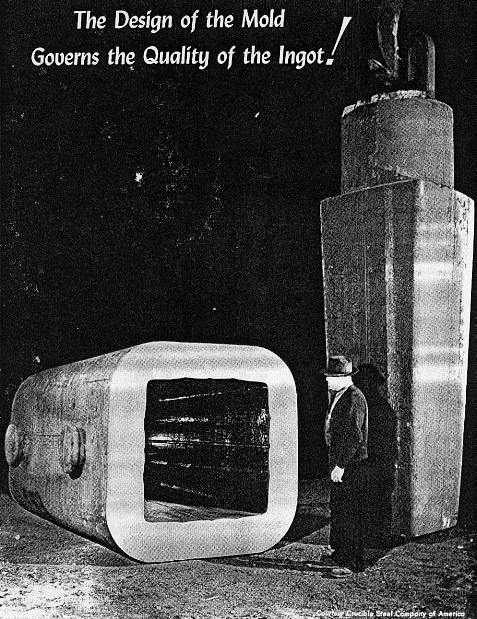

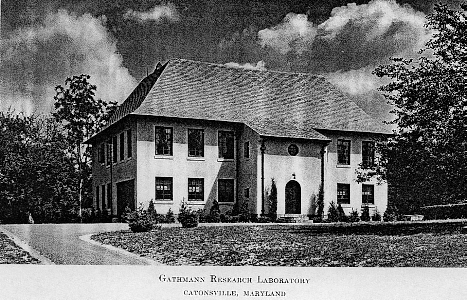

There is a lot of documentation and information out there on Emil Gathmann. This is in part because of his inventions, and in part because of the era he lived in. Most of Emil's inventions were related to the steel industry, more specifically ingots. "No steel product is sounder than the ingot from which it is produced. "Because this is so, the subject of sound ingots is of tremendous importance to us all, whether the product of the ingot is a cable for a Hudson River Bridge, columns for a Chryslwe Building or a steering mechanism for a Ford car. Certainly a railway rail, a boiler plate or any structural shape subject to serve stresses should be free from every possible defect. "Many users of steel demand quality- and quality at a price. This would be an unreasonable attitude, many steel producers believe it is, if it were not for the fact that many plants have proven that the demand can be met and met with profit. "By far the greater tonnage of steel produced is used in the making of products that may prove a jeopardy to life if unsound. Yet out of the 54,000,000 tons of steel ingots produced in 1929, only 5,000,000 tons were physically sound, i.e. properly finished and cast in big-end-up molds. At many plants the practice of producing big-end-down ingots is a legacy from a period when the knowledge of how to prevent unsoundness in steel in tonnage production was not available. Today, however, ingot molding is a science and there is little excuse for any producer who ignores its findings. "In the selection of a mold for producing sound steel, no sixth sense is required. A general knowledge of the mechanism of steel solidification is desireable, of course, but as a pocket watch may be selected by the past performance of a particular make, so with an ingot design. Gathmann designed big-end-up molds have been successfully employed in the production of some 30,000,000 tons of sound, homogeneous steel product, yields from ingot to bloom averaging eighty-two percent. "This record, of which we are proud, would have been impossible without the co-operation of our clients, who number the leaders in quality steel making. It is they to whom we are indebted for the progress made in the art of sound steel production during the past ten years. That we have risen from a half million tons of sound steel produced in 1920 to five million tons last year is indicative of what has been done. It is the writer's belief, however, that the next ten years will show even greater progress in quality production than ever before we can be brought to a realization of its importance."

What is an Ingot? During the production of metals, such as steel, iron, and others, the steel mill takes the ore and melts it down, and puts the liquid metal in a mold- an Ingot mold. The result is a mold with a solid piece of metal in it. The metal in this mold is an ingot. The ingots are then stripped, or taken out of the ingot molds, and are then sold to companies that melt them down into different metal products- such as steel bar stock, pipes, sheets, and so on. The metal is almost never heated and melted down as much as it is during the production of ingots. Because of this, most of the impurities in a metal can be traced back to the ingot they came from. The better the ingot mold, the sounder the ingot it makes. The sounder the ingot, the less impurities, and the more strength. Emil Gathmann perfected ingot molds, and the production of ingots. His son, Mark Gathmann (an employee of US Steel) took Emil's designs, and perfected them with his own ideas and designs, like Mark Gathmann's hot tops. Emil's patents for the metal industry were generally patented from the 1900's-1940's. Emil died in 1949, and would have kept patenting things beyond then- had he lived longer. He was patenting things all the way up through his death. To show Emil's massive amount of patents to the public, the drawings from each patent will (in time!) be put on this site. It should be pointed out that little has changed in the production of ingots since Emil died. The largest change was the use of more automatic tasks (computer controlled tasks, etc.), and the use of newer, more efficient machines. The actual production, and styles of the ingot molds have, however, stayed pretty much the same. The improvements made by engineers like Emil Gathmann in the steel & metal industry has allowed us to enjoy the use of strong steel products. Without such improvements in the steel industry, many of today's largest accomplishments would have never taken place. Space ships that took an American to the moon and back used solid, and sound metal, large buildings, like the WTC are & were made of sound and solid metals. Such improvements in such fields will be a large factor in insuring farther progress by mankind.

Want a quick tour of ingot production? Sure you do..... just click Here!

|